- Date

- 24th October 2024

- Categories

- Metered & Measured Energy Cooking Devices

By Professor Matt Leach and Malcolm Bricknell (MECS programme)

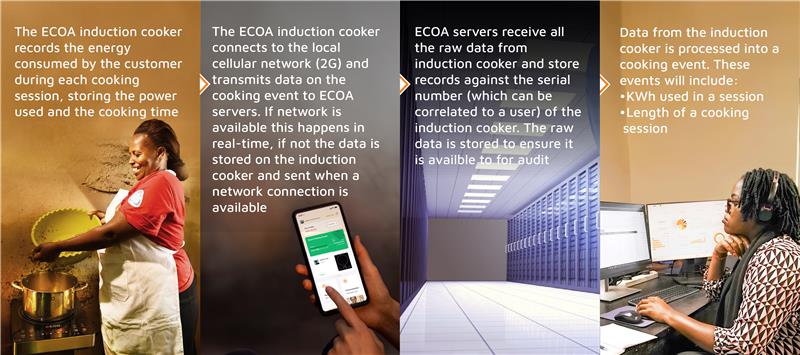

In a new report and accompanying blog, we set out the importance of digital approaches to underpin carbon credits from clean cooking projects. The voluntary carbon credit sector, including cooking, has been rocked by scandals over hidden failures in project delivery and independent assessments showing severe over-crediting. End-to-end digital Monitoring, Reporting and Verification (dMRV) is the new mantra across carbon markets for ensuring the necessary data are collected and kept secure, bringing transparency and accountability. For clean cooking, a vital element of this drive to high integrity credits is in the calculation of the energy and hence carbon emissions saved by the transition to higher tier stoves, whether more efficient in use of biomass fuels or also switching to cleaner energy sources.

As that report shows, techniques for digitally measuring or metering the energy used in baseline and then project scenarios, with new carbon credit methodologies designed for those, are starting to revolutionise the sector. The accurate calculation of emission reductions has led to ‘A’ ratings for projects by independent ratings agencies and are producing premium credit prices. The first methodology to be launched, and still the only one available, is the Gold Standard’s Methodology for Metered & Measured Energy Cooking Devices (MMECD). VERRA is developing a similar standard and the 4C Consortium’s Comprehensive Lowered Emission Assessment and Reporting (CLEAR) Methodology for Cooking Energy Transitions (CLEAR) is in draft, including several pathways involving metered data.

Carbon credits are already being issued from projects under the MMECD, many other projects are in development and our report quotes numerous companies for whom this approach now forms a core of their commercial plans. However, as for anything new, questions have been asked about details of the methodology. MECS was the originator (with CIP) of the MMECD, which was developed with and for Gold Standard; as such we have had numerous discussions with project developers getting to grips with the requirements. The two main areas of uncertainty have been why the methodology returns credit levels that seem to be lower than with traditional approaches and how to interpret and use some of the calculation parameters.

To provide an independent view and guidance, we commissioned the consultants AGS Carbon Advisory to conduct a study of the MMECD, comparing it to other methodologies, identifying the basis of any differences in results, and advising on potential improvements. Their report has just been published and offers good insights into the workings of the MMECD, and some recommendations for clarifications and further improvements. Here we set out the main findings and the implications of those.

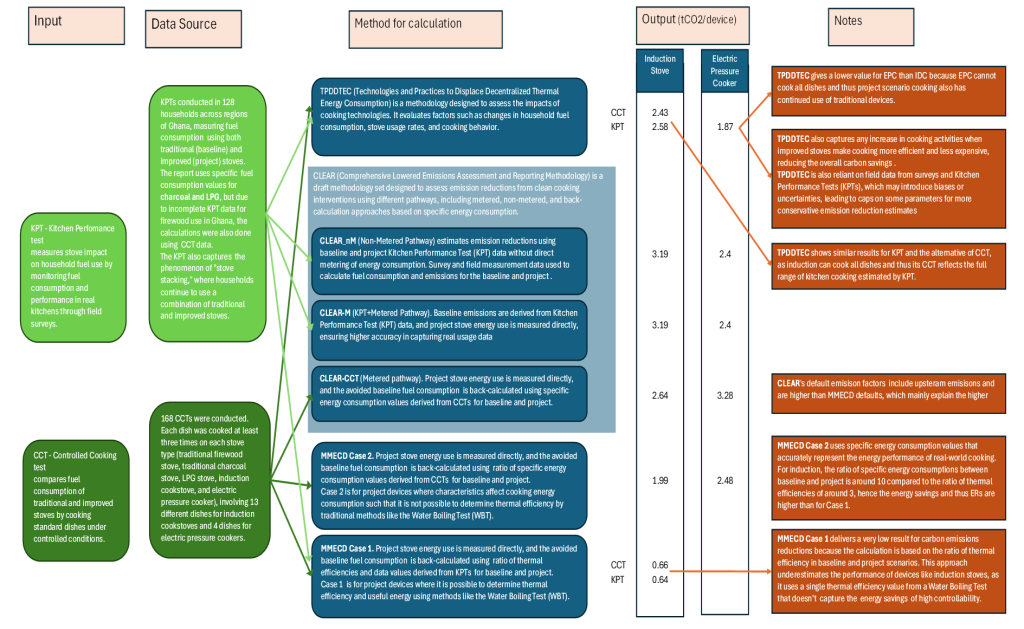

AGS were asked to do three things: compare MMECD with other leading methodologies, through a detailed clean cooking case study; review key MMECD assumptions and default values against sector norms; and compile recommendations for potential methodology improvements. The comparison methodologies chosen were the Technologies and Practices to Displace Decentralized Thermal Energy Consumption (TPDDTEC) v4.0 and appropriate pathways of the draft CLEAR, applying all of the methodologies with the same datasets. Detailed baseline and project Controlled Cooking Test (CCT) and Kitchen Performance Test (KPT) data for Ghana were provided by a project developer, looking at transitions from firewood, charcoal and LPG to Induction Cookstoves (IDC) and Electric Pressure Cookers (EPC) under various scenarios.

The headline findings of the AGS study are that the current MMECD methodology provides a robust yet conservative framework, yielding high quality Emission Reductions with strong environmental integrity. However, they also identify opportunities to improve clarity for how key procedures and data inputs can be applied consistently across different projects and suggest requirements for a more rigorous approach to sampling.

The figure below summarises the data used, scenarios and methods explored, with the main emission reduction results and some explanations of those. This is obviously a lot for one graphic, but the number of elements in the AGS study make it easy to get lost in a linear explanation, and hopefully this single view provides a useful perspective. The full details are in the AGS report.

Comparison of ERs between methodologies

A general conclusion is that the MMECD yields emission reductions that are comparable to other standards. A key uncertainty has been whether the ‘back-calculation’ of avoided baseline energy use from the metered project energy use leads to different results; TPDDTEC and CLEAR (nM) use surveys rather than metering for the project scenario and the results are comparable to the MMECD Case 2.

However, the results show clearly the importance of using realistic measures of the energy performance of cookstoves. MMECD Case 1 represents cookstove’s energy performance by a snapshot measure of their thermal energy efficiency, in the very particular circumstance of boiling water for 30 minutes. This is an industry standard Water Boiling Test and underpins the efficiency values often quoted for different stove types. The thermal efficiency of an induction stove might be 70% compared to 20% for traditional fuels/stoves, so the energy needed in the project scenario would be around 30% of that in the baseline, with associated avoided emissions. Case 2 however is based on the Specific Energy Consumption (SEC) for a stove when cooking the typical dishes in a project area: the SEC is the main output of a Controlled Cooking Test and a Kitchen Performance Test. The Ghana CCT data shows that the induction stove cooked the same dishes with around 10% of the energy needed to cook them using the range of traditional fuels/stoves. Thus Case 2 yields energy savings three times as high as Case 1, and hence a similar uplift in emission reduction.

Case 2 was established originally to do justice to the very high energy savings of using a pressure cooker, and for which a water boiling test is technically inappropriate. But this study demonstrates that ERs should be based on SEC for other highly controllable and efficient devices, such as an induction stove. TPDDTEC and CLEAR (nM), which estimate actual energy use in baseline and project scenarios rather than using efficiencies or SECs show similar results to Case 2, confirming the accuracy of the back-calculation approach using SECs.

There is considerable debate in the sector about whether CCTs or KPTs are more accurate. The report identifies strengths and weaknesses for each, but with particular risks for survey-based methods, and the quantitative results indicate that the choice may not affect ER results very much. TPDDTEC was tried using both datasets, and some of the CLEAR pathways use one and some the other.

One general trend in the results is that CLEAR gives slightly higher ERs than MMECD. CLEAR is still in draft and the 4C consortium are currently working through hundreds of comments from stakeholders consulted, so details may well evolve. However, the AGS study identified the key difference as being in the default emission factors for the baseline fuels: the CLEAR default values are higher than the defaults in MMECD, in part by allowing inclusion of upstream emissions. MMECD allows project developers to argue for use of higher emission factors, with upper caps set at similar levels to the CLEAR defaults, and this leads to similar ERs to those seen for CLEAR.

Parameters and guidance

Given the importance of SEC in the MMECD, the AGS study reviewed what the methodology gives as default values (which are at present only allowed for micro-scale projects, requiring developers of larger projects to conduct their own CCTs). The SECs found from the detailed Ghana CCT data are very close to the defaults, which were adopted by GS from a MECS working paper, latterly published in a journal. The analysis for the journal paper reports the median SEC values from a statistical analysis of hundreds of datapoints from many different field studies. The AGS study validates the defaults in the methodology and concludes that they could be allowed for use for larger projects too.

In applying the MMECD, the consultants came across a number of uncertainties in how key parameters should be used, most importantly the amount of baseline fuel used per device, and the proportion of baseline cooking per device. They recommend improved guidance in the MMECD itself and in the accompanying template spreadsheet, to ensure consistency in how developers apply data and calculations, and how assessors view these.

Finally, the report looks carefully at the role and requirements for sampling in the MMECD. The consultants note that while sampling is allowed, GS seem to encourage measurement or metering of all devices. AGS explore the risks in sampling and suggest specific incentives for full measurement or metering. Where sampling is to be permitted, they provide suggestions for strengthening the MMECD requirements, based on a review of best practices.

In conclusion, this detailed report concludes that the MMECD is a robust methodology, yielding relatively conservative emission reductions and hence credits with high environmental integrity. This reinforces the widely-held view that measured and metered methodologies are the best-in-class for higher tier cookstoves. The report also provides practical recommendations for further strengthening the methodology and providing clearer guidance, so project developers find it easier to implement.

***************************************************************************************************************

Featured Image: Copyright of BURN.