- Date

- 8th July 2021

- Categories

By Dr Simon Batchelor (Gamos Ltd.)

When I visited China (in Nov 2019 – which seems a long time ago now!), Nick Rousseau and I met with Mr Gao, lead designer of Midea. Midea are of course one of the leading manufacturers of EPCs and part of the Midea Group with a turnover of $41 billion.

We asked Midea if they would consider manufacturing a 600W version of the 6 litre EPC. Our understanding at that time was that most 6 litre (or more) versions are 1 kW or more, and that 3 litre versions are produced at around 700W.

Mr Gao had two pushbacks.

His first was that the flow of steam through the safety valve would be insufficient to shut the valve. If this was the case, there was a simple solution, to have the valve shut at the start of the process. The build up of pressure would therefore be in a closed environment. The valve is for safety, to prevent the top being opened under pressure. To start with it shut would not change this aspect as long as the only way to open the valve was by the internal space not being under pressure, as is the case now in all EPCs.

However, the second pushback was that with low power and a significant amount of cooking material, a 600W device would create a situation where the top and bottom of the material were at different temperatures and were cooking for a different period of time (potentially affecting the taste across the whole). This pushback seemed reasonable and so we have undertaken some experiments to test this hypothesis

The resulting working paper was originally circulated for discussion among the MECS team and those working on the Global Leap testing, and was originally not intended for publication. However, the information contained has proven useful for partners and collaborators and we now wish to place it on our website for wider use. (June 2021). It remains a working paper for comment.

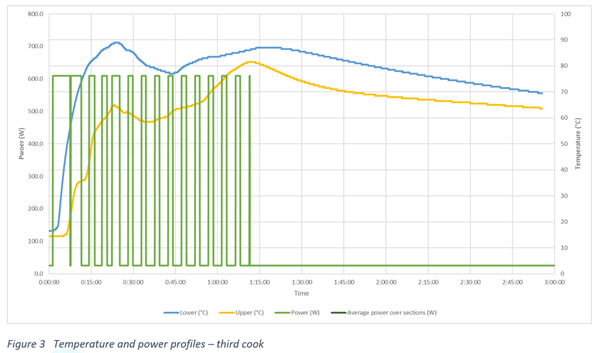

The blue line is the temperature at the base of the pan, while the yellow is the temperature at the top of the pan – for a very dense cook of mashed beans. So Mr Gao was right to say that there could be a temperature differential, but we don’t believe this is a function of power, more of the density of the material. Such an effect can occur in any EPC that has a compacted dense mass with limited convectional flow. You will see that we conclude that the ‘density’ of the material is what is important rather than the volume of material per se, or the power of the heating element.

………………………………………………..

Image credit: Jon Leary (MECS), 2019.