- Date

- 24th August 2021

- Categories

By Dr. Simon Batchelor, Loughborough University / Gamos Ltd.

Direct current (DC) appliances could be important for the off-grid electricity sector. While progress has been made on grid electrification, there are still 770 million who do not have a connection to a grid for modern energy access (IEA 2020). The progress in electrification has been uneven, and the majority of the unconnected are situated in sub-Saharan Africa. The World Bank estimates that by 2030, 500 million of these could be supplied by mini grids (World Bank 2020) with a balance having solar home systems. The majority of mini grids are now AC networks, so the demand for DC appliances is relatively small. Nevertheless there may be a role for the really remote rural areas for Direct Current Solar Home Systems, and for that reason we have been exploring DC appliances.

While we hope manufacturers will realise that there is a market for DC appliances for off-grid use, we thought the market might be so small that it could remain a neglected appliance. To fill that supply gap we considered a DC conversion kit which could take any AC Electric Pressure Cooker, and convert it to use with a supply from a battery (without the usual inverter).

This working paper was produced mainly by Conficio, a design agency. Conficio were commissioned to investigate the possibility of making a DC conversion kit for AC electric pressure cookers (EPCs). This would enable AC EPCs to be used by customers situated in rural, off-grid regions with access to DC electricity supplied via Solar Home Systems. Working alongside Gamos, Conficio undertook Stage 1 and 2 investigations of the constraints of commercial EPCs, and what this might mean for designing such a DC conversion kit.

Whether there is a need for a DC conversion kit remains unclear. The work was commissioned because, as most of the readers of the MECS blogs will know, electric pressure cookers have been found to be very energy efficient cooking devices. However, while there are many EPCs on the market designed for the alternating current grid (as shown in the Global Leap Buyers Guide), there are few, if any, reliable direct current appliances. The MECS team has investigated three DC EPCs, and found two of them had quality concerns (working papers here and here), while the other was of good quality but was a relatively small pot (working paper here). Just recently the eWant factory have announced a 5L capacity DC EPC, and at the time of writing we are waiting for the first sample to be assured that the quality is the same as their smaller version.

This report discusses the main design aspects of the switch mode power supply created to run the heating element of an Amazon Basics pressure cooker with DC. The requirements listed below necessitated that the design to achieve a maximum of 200V DC to achieve 800W of heating power through the fixed resistance of the heating element.

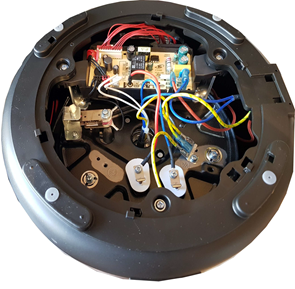

The desire was to make as few changes as possible to the existing pressure cooker layout and only change the control Printed Circuit Board Assembly (PCBA) and the input wiring and connector. This would then reuse the existing connectors and wiring and therefore the ‘upgrade’ to a DC pressure cooker could be completed in minutes rather than hours.

This obviously gave the PCBA design a quite tight space restriction limiting the size of devices used and the number of devices. The input current to the system potentially could exceed 35A therefore the weight of the copper required for some of the tracking would need to be 4oz; this is generally 4 times thicker than a regular construction.

The PCBA generally had all the power devices on one side of the board and the microcontroller and lower power devices on the other. As the weight and therefore thickness of the copper increases so do minimum track sizes, component pads and clearance distances. This means that a maximum of 2oz copper could be used on the underside of the board and, since board construction must be symmetrical, 2oz copper had to be used on the top.

Only 70% to 75% efficiency was achieved, and it was not possible to run for more than a few minutes before damage was caused to the low side Metal Oxide Semiconductor Field Effect Transistors (MOSFETs). Replacing these devices is a difficult task due to the thickness of the copper and the proximity of other components. It is therefore recommended that a larger PCB is designed with the purpose of performing more experimental observations with slightly differing snubber networks.

The MECS philosophy is about learning so the working paper provides a more in-depth examination of the design and the characteristics of the component parts used and their influences on losses and therefore efficiency in the system.

The Conficio reports were intended for discussion with the client (MECS through Gamos) and was not originally intended for publication (although all work within MECS is open source). The information contained could potentially prove useful for partners and collaborators and we now wish to place it on our website for wider use (August 2021). It is presented as a working paper for comment.

…………………………………………………

Featured image: Exposed base of an Amazon Basics EPC (image credit: Simon Batchelor, 2021).