- Date

- 8th February 2024

- Categories

- Induction Stoves

By Dr Simon Batchelor (Gamos Ltd.; Loughborough University).

In the original series of Star Trek, there were many times in an episode when Captain Kirk asked his engineer, Scotty, to give him more power. Facing some terrible danger there was often the cry “We need more power Scotty”, to which Scotty generally replied “I am giving you all I’ve got Captain”. The lack of automation, feedback and control on the standard induction stove is a potential weakness requiring user training.

I will come back to the relevance of that opening down below. We have already discussed in our blogs the energy efficiency advantage of induction stoves. The transfer of heat, or indeed the creation of heat, by the stove in the pan, means that there are fewer losses than a resistive heater with a poorly fitting pan. Induction stoves are said to convert electricity to heat in the pan at about 80% efficiency, and resistive heaters are quoted at 65%.

That is fairly consistent with our studies across many countries which show that in real kitchens across multiple types of food and when using a range of good and bad fitting pans, an induction stove is between 15 to 20% more efficient than a resistive hotplate.

I have purposely been careful in my language so far, talking about ‘poorly’ and ‘good fitting’ pans. The induction stove, by creating the heat in the pot itself, can have a small or a large pot sitting on it, and there is minimal wastage of heat to the surrounds. On the other hand, a resistive heater with a small pot, wastes heat up the sides of the pan. However a resistive heater with an excellent fitting pot, such as found in an electric pressure cooker, eg the SESCOM MY-CJ6001W can match the induction stove transfer efficiency and transfers at about 80% efficiency during the heating phase.

Of course the induction stove needs cookware within which it can induce a fluctuating magnetic field and create the heat. The quality of the cookware also affects this efficiency, and poor quality cookware can reduce the efficacy of the induction stove.

When we consider the energy efficiency of the induction stove in cooking a meal, there are two other elements that come into play.

At the moment induction suppliers, even though they may offer cookware as part of the package, do not include a pot with insulation or an air gap. Our studies show that the EPC is about 50% more efficient than a resistive hotplate. The efficiency of the EPC is achieved not only by cooking at pressure, but also through a combination of automated control of the power input and an insulating air gap between the pan and the outside world. A pot of beans 30 cm in diameter and with 15 cm of water and beans in it, when it simmers at 100 degrees can lose up to 400 W in convective and radiant heat from its sides. In an EPC the internal surfaces of the outer side of the air gap reflect back that radiant heat, back into the pot. At the very start of MECS, some lab technicians attempted to improve the insulating effect of the air gap thinking that a simple air gap was not enough. They found that adding more material for insulation reduced the efficiencies – which we think is because the radiant heat is not reflected back into the pot but heats up the thermal mass of the insulating material and an air gap is effective in ‘trapping’ air which is a good insulator (poor conductivity, and not so much convection losses).

So our point is that even a simple air gap can increase energy efficiency for long boiling of food in a deep pot. An air-gaped insulated deep pot for simmering is something most induction stove suppliers do not yet bundle in their cookware package.

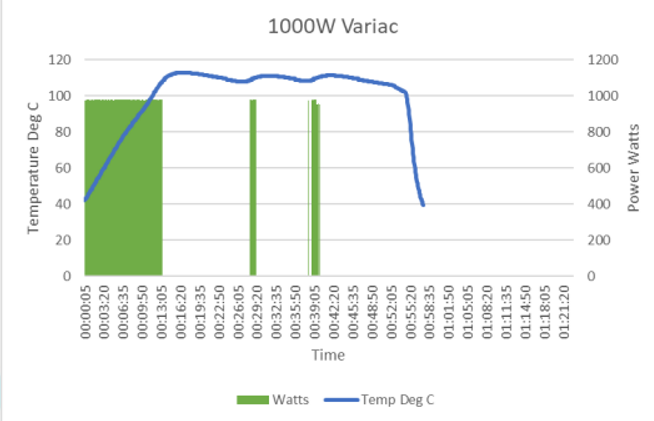

The other factor that comes into play with an EPC and is not embedded in an induction stove, is control of the heat. Most EPCs are user controlled through a timer – you set for how long you want the food to be at pressure. You can fry onions etc through the ‘no lid’, saute, or fry button, which just keeps the power on. But for any pressurized meal, after the heating phase, the pressure is held for the given time but with minimal input of energy. Once the EPC reaches pressure the device switches off, and only when it senses the pressure has dropped significantly, does it switch itself back on briefly to bring the food back up to full pressure (see Figures 4, 5 and 6 in this example of variable power input to an EPC). It is therefore very ‘minimalist’ in its use of the heating element when at pressure.

Most basic induction stoves in contrast, do not have a feedback mechanism. The user sets the power level. So at the start, the heating phase on a pot of beans and water to be boiled, the user is likely to set the device to ‘full power’. If the user remains in the kitchen, then when they see the water is brought to boiling they might turn down the stove to simmer. They may guess the power required to keep the pot in balance at 100 degrees C. Too much power and the pot goes to a rolling boil, letting off the excess power in the form of steam (water doesn’t go above 100 degrees unless it is pressurised). Too little power and the bubbling of the simmer ceases as the losses from the pot exceed the power going in, and the user may either turn the stove up or if they have left the room may come back disappointed to find that its no longer simmering*.

This manual control of the power setting is, in our opinion, a slight weakness of the induction stove. Under some conditions and protocols, there have been tests that found that induction used more energy than resistive elements. It turned out that this was due to the ways in which participating cooks controlled the different electrical appliances. They tended to use the highest power settings in order to get food to cook quickly. This meant that high powered devices (such as induction hobs) used more energy, although they were investing all that extra energy in steam! While some test protocols allow cooks to decide how to control stoves, others seek to minimise the influence of cooks as much as possible. However, this also has its limitations, as explained in this blog by Nigel Scott.

More sophisticated high end induction stoves can now monitor the temperature in the pot, and adjust the power input automatically. But the basic low cost induction stoves do not, which may in the long run be a false economy since the user may use more energy than required. And there is a new generation of multi cookers which have very tight control the power input and have feedback mechanisms such that you can set the temperature you want it to cook at and it will adjust accordingly. We will report on some of these new generation multi cookers in a subsequent blog.

*Just before concluding can I also make two side points:- first, of course lids are VERY important in energy conservation. A pot simmering without a lid will use a lot more energy than one with. Secondly, it is worth noting that food continues to cook at above 60 to 70 degrees C. Beans need an initial 20 minute simmer at near 100 degrees, but thereafter could continue to cook and soften even if the water (due to the low power setting) gradually falls to say 70 to 80 degrees – so too low a power setting after the first boil is not a disaster.

To conclude the blog though, let me come back to my main point:- the lack of automation, feedback and control on the standard induction stove is a potential weakness requiring user training. Having brought the water to boil, the simmering needs less power Scotty, not more power. We might need Captain Kirk standing behind the user, shouting, “we need less power Scotty”.

……………………………………..

Featured image, top: Image courtesy of Wikipedia based on Fair Use.