- Date

- 14th January 2025

- Categories

- Biogas

By Dr. Richard Sieff (Gamos Ltd.)

Introduction

Biogas and natural gas are abundant with huge potential to provide modern energy cooking solutions, save for one critical issue – the need for piped gas infrastructure. Both gases are typically used in piped systems as bottling requires much more storage space compared to denser fuels such as liquefied petroleum gas (LPG). These characteristics mean that where communities lack piped infrastructure, access to gas is typically limited to bottled LPG which can be more polluting and usually more costly than biogas or natural gas alternatives.

The US company Cenergy Solutions’ Adsorbed Biogas/Natural Gas (ABG/ANG) technology is designed to address this challenge by enabling biogas and natural gas to be stored in high densities at low pressure, using cylinders filled with activated carbon particles which adsorb gas molecules. Developed in 2012, the technology has been deployed in nine sites including Lamphun Province, Thailand where MECS was invited in October to a demonstration visit to see how the technology has been used by households, small business, and institutions.

Organised by the Nigerian company Data Analytics and Solutions Ltd (DAS) and the Nigeria Midstream Downstream Petroleum Regulatory Authority, the main purpose of the visit was to assess the applicability of ABG/ANG for Nigeria. The country has vast biogas and natural gas resources which suggest significant potential for ABG/ANG to lower living costs and offer cleaner fuel solutions for large numbers of Nigerian households, the vast majority of whom are currently dependent on more expensive and polluting fuels for cooking.

Cenergy Solutions’ adsorbed biogas/natural gas technology

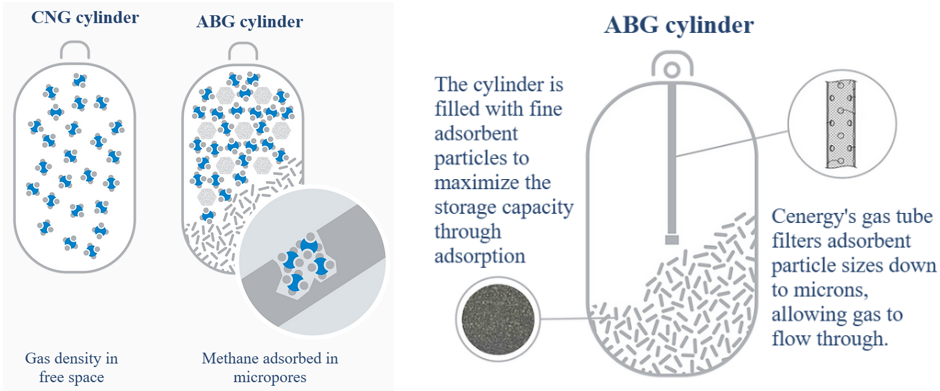

The Cenergy Solutions’ technology uses cylinders (or tanks) filled with adsorbent particles made of synthetic or organic material to attract methane molecules, making the molecules denser inside the cylinder and increasing

the energy stored per square cm. The process allows the cylinders to be filled with natural gas or biogas at low pressures, supporting cooking by reducing the cost associated with high-pressure compression and the danger of storing at high pressure. The key to the technology is the patented filter which addresses the difficulty of keeping the adsorbents (as small as 5 microns) inside the cylinder when the gas is used – the main challenge for other companies trying to commercialize ABG/ANG. Thus, in a sense, the key to addressing the bottleneck is the bottle neck itself.

Two main types of cylinder are offered: composite and repurposed steel LPG cylinders. Each is available in a range of sizes, either with or without adsorbent material, and can use different valve types to handle different pressures (either 20bar or 40bar). Storage (gas/cm3) is increased when using composite cylinders, adsorbent, and higher pressure (Table 1).

The technology is methane agnostic, allowing for the use of varied feedstock sources such as pipeline gas, biogas, methane-rich environments (e.g. Rwanda’s Lake Kivu), and flared gas. Use of the latter can help mitigate gas flaring, a hugely wasteful practice and major source of global CO2 emissions (IEA, 2024).

| Colour | Size | Pressure | Adsorbent | Storage (cubic m)1 | Gas stored2 |

|---|---|---|---|---|---|

| White steel cylinder | 43L | 20 bar | N | 0.9 | – |

| Red composite cylinder | 30L | 20 bar | Y | 1.84 | 3kg |

| Blue composite cylinder | 47L | 40 bar | Y | 5 | 5.5-6kg |

| White steel cylinder | 100L | 20 bar | N | – | 6.5-7kg |

Cooking with ABG – key takeaways from Thailand

During the visit, the key focus for MECS was of course the cooking. Demonstrations at Cenergy Solutions’ offices showed the technology worked in terms of delivering a consistent flame for cooking which could be used with various appliances. Two local households, three businesses and a school were subsequently visited, with all reporting they used ABG (ANG was not being used at the sites visited) for all or almost all their cooking and were happy with the cooking performance of the technology. Other key takeaways included:

- The households highlighted that cooking with ABG was quicker than with LPG (their previous primary cooking fuel) and made cleaning pots easier. One household reported 50% savings in cooking fuel costs after shifting from using one 15kg LPG cylinder to two 47L ABG (20 bar/composite) cylinders per month.

- A restaurant visited also noted lower cooking costs despite needing to order cylinder refills every three days (via a group chat with Cenergy Solutions). The Data Analytics team highlighted that delivery costs are built into the price of the refill to help maintain a lower price point than LPG.

- At the Cenergy Solutions’ office, the ABG cylinders were also used to power small generators for common appliances (e.g. fans and lights) and a rickshaw. The company’s refilling system was also demonstrated. Hydrogen Sulfide (H2S) is separated from the biogas as it can corrode roofs and other metals in people’s homes. The system also dries the biogas to avoid moisture taking up cylinder space.

Another example of biogas use during the visit was a local school’s use of a 5m3 on-site biodigester to pipe biogas directly to the school’s kitchen. Staff at the school reported that all cooking was now carried out using this more conventional form of biogas, replacing the four 15kg LPG cylinders previously consumed per month. All inputs to the biodigester came from school meal scraps while the slurry from the biodigester was used as fertiliser for the school gardens.

The Nigerian case and business model

In keeping with the model used in Thailand, The ABG/ANG model proposed for Nigeria is based on selling gas, not cylinders. Households will only be able to refill their Cenergy Solutions cylinders via distribution houses – a design intended to support regulation and safety by preventing poor quality cylinders from other providers being used. The model intends to promote social inclusion, with women proposed as the owners of the distribution houses (one per 100 households) and youths employed to deliver and collect cylinders. The assumed disadvantage of ABG cylinders needing more regular refills than their LPG equivalents is seen as an advantage for the business model and livelihoods as more refills mean the youth make more trips collecting and delivering cylinders, and earn more income. A smart regulator for the cylinders has also been developed to inform households and distributors of refill needs and support plans for future carbon finance applications.

The initial customer segment targeted in Nigeria are households which buy fuelwood daily for cooking and do not usually use gas. The rationale for targeting this segment seems logical. The composite (30L, 20 bar) cylinders storing 3kg of gas proposed for distribution are expected to provide several days of cooking, therefore offering a marked improvement in terms of reducing the frequency with which households purchase fuel, as well as providing cleaner cooking and lower fuel costs in a price sensitive market. The 3kg cylinder was selected owing to the familiarity of this size due to the widespread use of 3kg LPG cylinders across Africa. The cylinders will be referred to as ‘low pressure’ in Nigeria, with the term ‘adsorbed gas’ considered less likely to be understood.

Latest developments

Since the demonstration visit, there has been hugely positive news for Data Analytics & Solutions (DAS) who signed a partnership with the Nigerian Federal Ministry of Innovation, Science and Technology (FMIST) to implement the Cenergy Solutions’ ABG/ANG technology through sustainable energy access projects (SEAPs) across all 774 local government areas (LGAs) in Nigeria. FMIST Minister, Chief Uche Nnaji announced that “Through SEAP, DAS will replace biomass in 20,000 households per LGA with clean, low-pressure compressed natural gas and biogas alternatives” – the total 15.5m households equating to almost a third of Nigeria’s 43m households.

Under the SEAP partnership, biogas is to be initially prioritised as the feedstock for the cylinders in each LGA, with the liquid fertiliser biproduct used to reduce current demand for expensive synthetic fertilizer. Where natural gas is used, the focus will be on using flared gas as the feedstock, providing cleaner cooking solutions to local communities living near the flare sites and contending with their harmful health and environmental impacts. The SEAP partnership is also intended to improve power supply by delivering at least 5 MW of hybrid gas and solar power to each LGA and establishing battery swap centres for electric tricycles and bikes at 33,000 petrol stations.

Further opportunities for ABG/ANG?

The SEAP partnership suggests opportunities may exist in other countries for scaled ABG/ANG cooking solutions – the case for which may be strengthened by additional research. Controlled cooking tests can help identify potential energy, time and cost savings relative to other cooking fuels when preparing local menus. Kitchen performance tests and/or cooking diaries can also highlight potential savings as well as provide insights on cultural acceptability and user preferences in different locations, including where fuel stacking alongside other modern energy cooking solutions, such as highly efficient electric cooking appliances, may be optimal. Establishing common standards for ABG/ANG could also streamline deployment across regions by ensuring regulatory compliance, while there may be scope for carbon finance applications to further reduce costs.

…………………………………

Featured image, top: Demonstration at a local enterprise of cooking using a Cenergy Solutions ABG cylinder (left) and an LPG cylinder (right) (photo credit: Richard Sieff).