- Date

- 10th December 2019

- Categories

By Dr Nigel Monk, CREST

Why are CREST performing technical tests? The ‘Centre for Renewable Energy Systems Technology’ (aka MECS_Techs to our friends, which includes everyone) at Loughborough University are the technical lead on the MECS programme. Starting from the proposition that almost half the world’s population routinely don’t cook using electricity – they’re off-grid, suffer a weak grid, or can’t afford the electricity, and frequently have no access to bottled gas either – as is often the case, a simple idea to provide battery supported electric cooking equals the 1% inspiration. Technically, the remaining 99% is still not achievable at appropriate cost, time, quality and equipment life expectancies.

CREST are creating systems and testing components to ensure the device will work and last in the field and that quality is not lost; time is predicted to bring the costs into range. Part of the work – assessing component parts or systems elements – is to protect the battery capacity and life expectancy. That’s the key weakness. We’re looking behind the manufacturer’s rating label claims and headlines using a well-equipped state-of-the-art laboratory to move out of the kitchen laboratory, to produce repeatable science, to form the foundation to move back into the kitchen laboratory… eh? Well, there’s a need for both, at appropriate times.

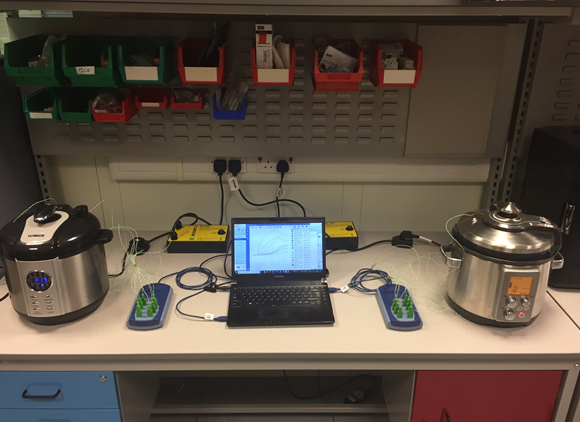

CREST are using easily characterised and repeatable cooking loads, i.e. water. That allows us to assess hardware (and firmware and software) performance unambiguously. But cooked water tastes like water regardless so there is a need to let the cooks loose on the appliances in-country to discover how their use of the system while cooking real meals affects the predicted energy use (it can only get worse!) and, most important of all, whether the food tastes ok!! So, we characterise standard products like electric pressure cookers (EPCs) to understand the science behind their behaviour in detail, so we can identify how the cooks’ behaviours are affecting energy consumption and use that knowledge to design a better EPC, or better way of configuring the system, or better way to persuade the cooks of the advantages of behaving differently…

As it happens, CREST have recently released several working papers; primarily reports containing factual observations and test data. One such, “An Investigation into the Functionality and Efficiency of an Electric Pressure Cooker Bought in Kenya” consumed two months of testing, data analysis and analysis development to produce two small graphs (and a very detailed report). Taking a step back, why consider EPC’s at all? Perceived wisdom is they are good for one-pot meals, but manufacturers aiming at affluent markets heighten utility by adding ‘elaboration’, i.e. non-essential functionality, in the form of pre-programmed cooking programmes, complex controls, all in the name of ease of (and expansion of) usability; many are ‘7 in 1’ cookers. Ironically, that approach makes the product less applicable to the global south, MECS’ market, because the language assumes cultural norms, the foods are western, the whole is inaccessibly complex. Recipe books provided with the appliance focus on hours of preparation followed by minutes of cooking. Such energy profligacy obscures the potential value of an EPC and the ‘why’ is in this report.

However, a little ingenuity and not a little effort has led to the brilliant MECS publication Kenya eCookbook which adapts popular and staple Kenyan foods to cooking using an EPC. The booklet demonstrates how much real money saving can be gained. For all the reasons above, we pursued the bought-in-country EPC test and report. It is highly suitable and very good; I’ll leave the reader to decide which refers to which.

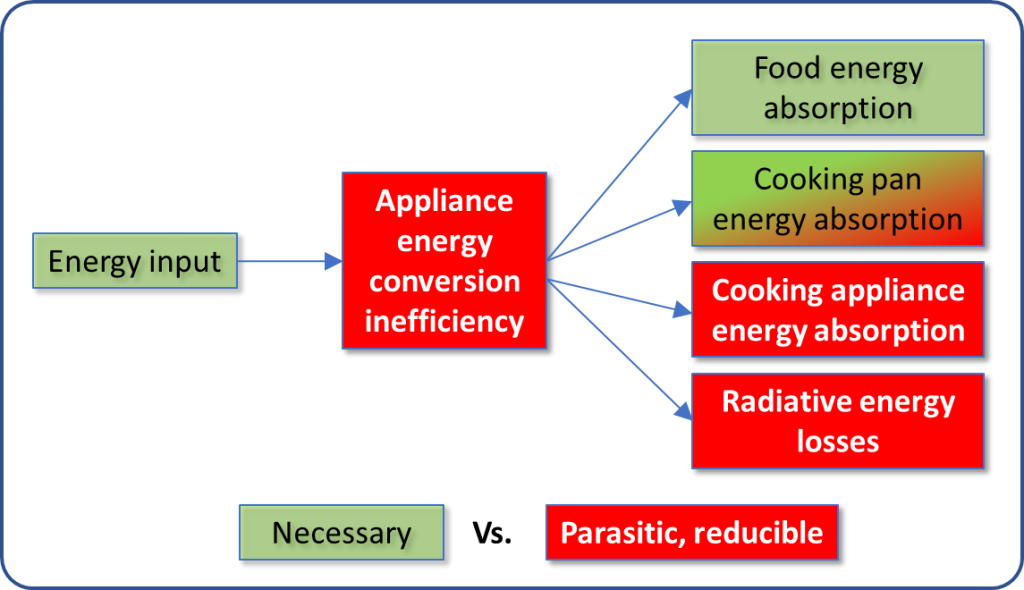

So, where next? We – CREST & MECS – are not only considering EPCs; in ambition, we are appliance and fuel impartial, but we have to start somewhere. In future, we will compare the Sayona EPC with a number of western EPCs that appear to potentially offer advantages, to discover if they actually do, and against other appliance types and systems, to fill the areas around the EPC niche. We can use a framework like below to think about how a particular appliance type supports a low-energy, high-efficiency solution. Better still, consider whole-systems up to mini and micro grids with MECS programme partners. Looking outwards, we must start to work with manufacturers and others on the considerable scale-up needed.