- Date

- 25th October 2023

- Categories

- Electric Cooking, Induction Stoves

By Dr Nigel Scott and Prof. Matthew Leach

In this blog we address the question raised as to whether scaled use of induction stoves for cooking could create any additional power quality problems. Spoiler alert – the answer is no.

Induction stoves are a popular and well understood member of the family of modern, energy efficient electric cooking devices. In an earlier blog, Prof. Matt Leach described recent concerns in the global north over the health impacts of cooking with gas. He highlighted the role of both induction stoves and electric pressure cookers in transitioning away from gas to electric cooking. In a low income context, induction stoves are popular because of their flexibility – they can cook most dishes that are cooked in a pot, much as they would be using a traditional wood, charcoal or LPG stove. They are also more efficient than a resistive hotplate. Recent work indicates that when used in kitchens in low income countries, induction stoves can use 20% less electricity than traditional resistive element stoves. However, much of this saving is a result of traditional stoves being used carelessly – if the pot does not cover the entire surface of the ring, then heat being emitted from the uncovered part of the ring is wasted. (You can find a more detailed discussion here).

Induction stoves work by generating a rapidly fluctuating magnetic field that couples with the bottom of a steel (or ferromagnetic) pot. The changing magnetic field creates eddy currents in the bottom of the pot. A combination of eddy currents and magnetic hysteresis then generates heat in the base of the pot (you can find a simple explanation here).

Any physics book will tell us that energy is stored in the magnetic field of an electromagnetic coil; when the AC reverses polarity and the voltage drops, the energy in the magnetic field is released, but the resulting current is out of phase with the mains. This energy sloshes back and forth between the coil and the grid, resulting in no net power drawn from the grid. There is, however, an increase in the current drawn. In this way inductive loads are said to draw ‘reactive’ power from the network. Note that reactive power does not represent real work but is simply a way of handling the current that is out of phase with the mains. This reduces the power factor (from a value of 1 for a purely resistive load) and can cause problems in electricity networks by introducing unnecessary losses. This understanding of physics has, quite reasonably, prompted some concern that induction stoves might cause problems when connected to distribution networks, especially if adopted at scale so that large numbers are connected to the same low voltage network.

This blog has been written to assure readers that this is not the case. Several studies have shown that the power factor of commercial induction stoves is near unity i.e., they do not present significant inductive load to the grid. A 2014 study by the Electric Power Research Institute (EPRI) in the USA looked at two single hob induction stoves and measured a power factor of 0.98 and above. Another study by Lulea University, also from 2014, examined distortions to current and voltage waveforms introduced by a number of domestic appliances, including an induction stove. It describes how the power factor of an induction stove is corrected. First, mains AC is rectified to DC, which supplies the workings of the stove. The ‘pancake’ induction coil is supplied by a ‘tank’ or ‘resonant’ circuit that is controlled by micro-chips that vary the frequency of the oscillating current, and an active power factor correction circuit ensures that the mains does not see an inductive load. This also explains how an induction stove achieves better control of the cooking temperature. There are two ways in which cooking power can be controlled – either by modulating the power to a lower level that is delivered continuously, or a simpler method is to deliver power at a constant level but cycle it ON and OFF, spending less time in the ON state at lower power settings. Spiral resistive coil stoves simply cycle off and on again at full power. Induction stoves, on the other hand, can deliver continuous power down to 50% or even 30% of the rated power by controlling the frequency of the oscillating current in the induction coil (power is reduced by increasing the frequency).

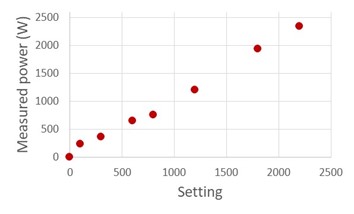

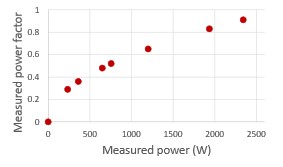

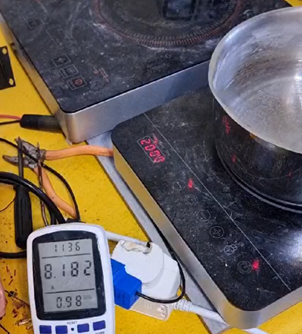

Our own tests on a single hob induction stove confirmed that continuous power was modulated down to just over 50% of the rated power (see Figure 2). At lower power settings, we found the induction stove cycled ON and OFF at 1,100 W, so control was a mix of both modulation and cycling. We also measured near unity power factor at all levels of power drawn except in standby mode when the stove drew 100W. At this low power level, the simple plug-in monitor registered a power factor approaching zero, but we suspect this to be inaccurate.

Regulating current using chips usually results in some distortion of the sinusoidal waveform of an AC power supply, and this is true for cooking devices. However, the EPRI study found that the harmonic distortion of the current drawn by induction stoves was relatively low at less than 6%. Even if this does not mean much on its own, the important finding from both studies is that total harmonic distortion was well within international regulations.

Furthermore, studies have also shown that induction stoves can be rolled out at scale with no problems on the grid. Ecuador’s National Efficient Cooking Program (NECP) aimed to transition 3 million households from LPG to cooking with induction stoves. A 2017 study of the ‘Plan Fronteras’, which introduced 5,400 induction stoves into a single province, measured grid parameters and concluded that they were all within the limits of regulations. All transformer voltages were within 5% of the nominal voltage; the power factor at the network level was within limits, and the voltage total harmonic distortion was within limits, so the study concluded that rolling out induction stoves did not cause any problems on the electrical network. Note that device standards may play a role in ensuring that poor quality stoves do not introduce excessive harmonics.

Out of curiosity, we also tested a single hob infrared stove. The results were quite different to the induction stove. Firstly, the power was modulated all the way down to its lowest setting (100), although this actually delivered 230W (Figure 3). More importantly, the power factor appeared to deteriorate linearly with power delivered. Given that infrared is most commonly generated using tungsten filament heaters, we had expected the infrared stove to behave like a spiral coil stove, which is a purely resistive load (i.e. unity power factor). For the moment, we can only speculate that the variable power factor is due to the power control circuitry. We are not aware of any plans for scaled roll out of infrared stoves, mainly because they have been superseded in the market by induction stoves, which are more efficient. Nevertheless, we are keen to understand why, unlike induction stoves, they do have a variable power factor.

MECS is currently working with companies that are developing induction stoves specifically designed to meet the rigours of low income country markets. Both companies have plans to roll out substantial numbers of stoves in the next couple of years. MECS is also supporting African utility companies to promote electric cooking as a means of increasing customer demand. For example, Kenya Power aims to get 500,000 households cooking with electricity in the next 3 years, which may well include induction stoves. It will be interesting to learn how grids cope with additional cooking loads, but we don’t expect induction cooking to create any additional power quality problems.

Featured Image: Copyright of vectorjuice on Freepik (www.freepik.com)