- Date

- 16th November 2023

- Categories

- Electric Cooking, Induction Stoves

By Dr Nigel Scott (Gamos Ltd.)

In this blog, we show why it is important to use the right kind of pots when cooking on induction stoves. We consider the choice of materials to be used in the base of the pot and the way pots are constructed.

When conducting controlled cooking tests, MECS partners in Bhutan spotted that two different stove top pressure cookers used different amounts of energy. Initially, they found that using a stovetop pressure cooker with the induction stove used more energy than an infrared stove, which was not what they were expecting. So they repeated the tests with a different stovetop pressure cooker and found that the energy consumption dropped dramatically, by over 25% – see Figure 1. Note that other work has shown that induction stoves can use 20% less electricity than traditional resistive element stoves, so the test results from Bhutan indicated that the effect of the different pots was even greater than the efficiency gains expected from induction cooking. This prompted us to try and find out more about what affects the performance of different types of cookware.

Both pressure cookers were from well known Indian brands – TTK Prestige, and Kitchen Essentials. Both pressure cookers were described as having an induction bottom, so were specifically designed for use with induction stoves, but no details of their construction and materials are available on their websites, other than that they both have an aluminium body.

Basics of how induction cooking works

First, a bit of the physics of how induction cooking works. Induction stoves produce a high frequency alternating current that passes through a flat, pancake coil of very thin wire (see Figure 2). This creates a rapidly fluctuating magnetic field. When a ferromagnetic pot is placed near the coil (i.e. on top of the stove), the fluctuating magnetic field couples with the metal base of the pot and induces eddy currents to flow in the metal. The metal must offer a reasonable resistance to the flow of electricity in order to generate heat in the base of the pot. Magnetic hysteresis within the base of the pot is a second effect that contributes to the heating up of the pot. There are two key variables to consider when assessing the performance of induction cookware: the material used for the base of the pot, and the distance of the base from the magnetic coil.

The performance of different materials

An early study by the Electric Power Research Institute (2014) that compared the efficiency of different stove technologies also reported complaints that the compatibility of cookware with induction stoves was sensitive to the composition of the stainless steel used in the pot. Induction cooking works best with magnetic materials, as they offer both electrical resistance and magnetic hysteresis effects – it is often recommended to check induction cookware by testing if a magnet is attracted to it. Other metals such as aluminium and copper may not be magnetic, but they will still offer some electrical resistance, albeit relatively low, so in principle it should be possible to transfer energy to a pot made of these materials. Indeed, the studies referred to below include aluminium pots. However, many commonly available induction stoves are equipped with a pan detection feature that turns the stove off if a pot with a non-magnetic bottom is used.

A 2015 study from Ecuador measured differences in cooking efficiency when using pots made of different materials:

| Pot material | Energy efficiency (%) |

| Iron (enamelled) | 91% |

| Stainless steel | 87% |

| Aluminium | 82% |

This article on induction cooking indicated a slightly different order of pot materials and efficiencies, although we note there is no reference so it’s not clear whether these figures are based on laboratory tests. Nevertheless, it illustrates the point that even though conductive materials like copper and aluminium can work with induction stoves, they don’t work well.

| Pot material | Energy efficiency (%) |

| Stainless steel | 90% |

| Cast iron | 85% |

| Aluminium | 70% |

| Copper | 60% |

As previously noted, effective induction cooking requires the material in the base of the pot to provide reasonable electrical resistance to generate heat. The electrical resistance offered by a pot depends on two characteristics of the material: electrical resistivity and skin depth. Resistivity is a measure of how easy it is for electricity to pass through a block of material and is a physical property of the material. When an alternating current passes through a conductor, most of the current flows near the surface of the wire, or sheet. The skin depth represents the depth within which most of the current flows. Good conductors, like copper, have a thick skin depth, whereas electricity in poor conductors will only pass through a very thin layer near the surface. The skin depth decreases with increasing AC frequency. Surface resistance (in Ω, sometimes referred to as ohms square to distinguish it from normal resistance) is simply the resistivity divided by the skin depth and represents the resistance provided by a 1m x 1m sheet that is as thick as the skin depth. The actual resistance of a pot bottom could then be calculated using the surface area of the bottom of the pot (rather than a 1m by 1m square). In terms of comparing the efficiency of different pot materials, this measure of surface resistance is the most interesting.

Table 3 highlights some of the stainless steel grades more commonly used for kitchen purposes. Note that most steel suppliers have some information comparing the properties of different stainless steel grades, e.g. Thyssenkrupp, Marlin, Kloeckner, AAA.

| Stainless steel grade | Characteristics | Uses |

| 304 | Good corrosion resistance | The most widely used stainless steel; commonly used in kitchen equipment |

| 316 | Corrosion resistance (especially pitting), high strength | Any food application |

| 409 | Good for high temperatures | Commonly used in exhaust systems |

| 430 | Good atmospheric corrosion resistance, ductile, cheaper | Used for looks rather than strength |

Table 4 gives the electrical and magnetic properties of these four stainless steel grades used to calculate their surface resistance. Skin depth was calculated using an online calculator. The table clearly shows that the 300 series grades have a low surface resistance and are not good for induction cooking, whereas the 400 series grades are very good (corroborating findings from the Electric Power Research Institute (2014)). The 300 grades are both austenitic stainless steels, whereas the 400 series grades are ferritic stainless steels, which are magnetic (there is a lot to know about steels – Wikipedia is a good starting point). Aluminium and cast iron have been added to Table 4 because pots made of these materials were used in the studies referred to above. The studies do not explicitly state if aluminium pots were made of pure aluminium or alloys (figures in the table are for pure aluminium). Finding properties for cast iron is not straight forward as there are many different types even of grey cast iron, which is widely used in cookware (wiki ref.); the figures in the table are only estimates drawn from a number of sources, i.e. they do not represent specific cookware.

| Material | Resistivity | Relative permeability | Skin depth (at 24 kHz) | Surface resistance | Relative surface resistance (to copper) |

| (µΩ.cm) | (n/a) | (mm) | (Ω) | (n/a) | |

| 304 | 72 | 1 | 2.7 | 0.26 | 6.6 |

| 316 | 74 | 1 | 2.8 | 0.26 | 6.7 |

| 409 | 60 | 800 | 0.1 | 6.7 | 167 |

| 430 | 60 | 800 | 0.1 | 6.7 | 167 |

| Cast iron | 100 | 60 | 0.4 | 2.4 | 60 |

| Copper | 1.7 | 1 | 0.4 | 0.04 | 1.0 |

| Aluminium | 2.7 | 1 | 0.5 | 0.05 | 1.3 |

Pot construction

But pot manufacturers are not only interested in the magnetic properties of materials – they want an induction compatible pot to conduct heat quickly, to be strong, and to look nice. Unfortunately, materials that are good thermal conductors, like copper and aluminium, also have low electrical resistivity so they are not suited to induction cookware. However, layering materials offers a solution. Remember that eddy currents flow mostly within the skin depth of the material, which for magnetic stainless steels is relatively thin (e.g., 0.1 mm). This means that manufacturers can use multiple layers of different materials to get the thermal and strength characteristics they want, using just a thin layer of shiny, magnetic stainless steel on the outside to ensure good performance with induction stoves. Often referred to as ‘cladding’, several brands are available using this layered composite construction in their cookware (e.g. Made In).

Pot shape – and dents

Pot strength is interesting when it comes to induction cookware. Aluminium cooking pots are widely used in low income countries because they are cheap, good conductors, and can easily be made and repaired, although there are growing health concerns over the recycling of scrap aluminium alloys (e.g. lead). These kinds of pots are easily bashed and dented, which does not present a problem when cooking over an open fire. However, it does present a problem when cooking with electricity. When using a spiral coil stove, it is important to get as much contact as possible between the hot element and the pot in order to maximise the transfer of heat through conduction (which is most important – see this blog). If the base of the pot is dented (either concave or convex), leaving only a part of the base on contact with the coil, then heat can only be transferred through radiation and convection.

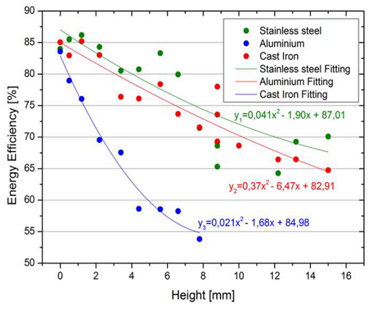

When using an induction stove, it is also important to use a pot with a flat bottom because the coupling of the magnetic field with the base of the pot decreases with distance from the induction coil. The Ecuador study demonstrated this effect by measuring the efficiency of induction cooking with the base of the pot held at different distances from the surface of the induction stove (see figure 4). As expected, the efficiency drops off as the gap increases, but the stove keeps working up to a gap of 15mm (for the ferrous pots). This implies that even if a pot has, say, 5mm dents then it will still work with good efficiency (around 80%).

As a general rule, cookware manufacturers often make pots slightly concave i.e., they stick up a bit in the middle. This means that when the pot is hot and the material expands, it flattens out, improving the contact of the base of the pot with the heat source (find a good explanation here). However, pots designed for induction stoves are often constructed with aluminium bodies and a ferromagnetic base. Where the two materials are bonded together on the base, they expand at different rates when heated up. Because the aluminium on the upper surface expands more than steel on the lower surface, the base ends up deforming to make it even more concave when it heats up. This introduces a gap between the base of the pot and the surface of the induction stove. Figure 3 suggests that, as long as this effect is moderate, this should have only a minimal effect on efficiency.

Conclusions

The conclusion of this investigation is nicely captured by this quote from The Induction Site: “merely being made of stainless steel does not make a piece of cookware “induction ready”.”

Our partners in Bhutan were right to recommend that the base of cookware should have an outer layer of 430 stainless steel (or other ferritic stainless steel) in order to achieve the benefits of induction cooking. Unfortunately, manufacturers do not usually give details of construction materials on websites or labels.

We should also point out that there are many different stainless steel specification systems, which makes it even more difficult to identify good induction cookware (e.g., Euronorm EN 10088 in Europe; AISI and ASTM series in the USA; ISO); the grades used in this article are based on the SAE system (Society of Automotive Engineers). These are all issues that standards agencies should address.

The findings clearly highlight that it’s not just the stove that needs to be considered when assessing the energy consumption implications of cooking with induction stoves. Given that using the wrong kind of pots can more than wipe out the efficiency benefits of induction stoves, attention needs to be paid to the pots to be used with induction stoves. Manufacturers are aware of the importance of this and are taking various approaches to making sure customers enjoy the full benefits of induction cooking. For example, BURN offer a bundle of induction stove with a three piece cookware set, and ATEC have published an “eCook cookware specification guideline” that gives specifications for pot materials, concavity and size.

Good induction compatible cookware is important for cooks seeking a better cooking experience and lower fuel costs, utilities looking to understand the likely energy demands of scaled induction stove adoption, and policymakers and other stakeholders seeking to deliver effective and sustainable induction stove programmes.

Featured Image: Stainless steel pot on induction hob. Image by Freepik (www.freepik.com)