- Date

- 11th February 2020

- Categories

By Matt Leach, MECS Gamos Associate, and Professor at the University of Surrey

A recent MECS working paper asks whether biogas in small cylinders has a role to play in modern energy for cooking in Africa.

Truly clean, sustainable and affordable options for cooking, as substitutes for traditional use of fuelwood or charcoal, are not easy to come by. The most obvious options involve electricity or gas as the final energy carrier. MECS is actively pursuing electric cooking; what about gas?

For decades, notably in China and India, ‘biogas’ (methane derived from some form of biomass, with varying proportions of CO2 and other substances) has been the key substitute for solid biomass fuels, using individual household-scale digesters fed from crop-, animal- and sometimes human-wastes. Several African countries have started national biogas programmes seeking to emulate this success. But household-scale biogas production doesn’t suit everyone, as it needs the household to have their own livestock and crop-residues, and a degree of day to day management. Liquefied Petroleum Gas (LPG) is gaining traction in many regions, offering user satisfaction and minimal infrastructure needed, with a global supply of gas. However the gas in question is almost exclusively derived from fossil fuels, during crude oil refining or from natural gas production, transported to the user in pressurised canisters. Can a fossil fuel for clean cooking be truly ‘modern’? ‘Green’ or bio-LPG is coming: a propane currently extracted as a co-product of biodiesel production. But it isn’t available yet at scale.

What about other ways to make bio-methane available for cooking in Africa? In many countries agriculture is the dominant industry, and there is no shortage of agri-residues and other biomass materials, much of which is currently a problem, requiring disposal. These residues are often already used very effectively for onsite process heating, and also for power generation, that may include excess exported to the grid. But with relatively low-density housing in surrounding communities, and low energy demands per household, building a gas pipe network to distribute excess biogas outside the agri-business is rarely realistic. Could you combine the utility of the LPG-style container with the ubiquity of biomass residues?

Faced with this question, the instinctive reaction of many engineers is to say “no”: Biogas is often contaminated with water, which won’t compress, and with other impurities, which can be harmful if burnt, so you’d need to do a lot of cleaning up, traditionally regarded as prohibited expensive at small scales. Moreover, raw biogas typically has a proportion of carbon dioxide (with no energetic value), reducing the calorific value of the gas and making for a weak cooking flame, as well as making it difficult to store enough for practical needs. The upshot is a traditional sad shake of the head at the suggestion of biogas bottling on any sort of a small, local scale.

This view seems to be out of date. There are technical challenges, but they can and have been solved through clever engineering for simpler and cheaper clean-up into ‘bio-methane’, with low cost pressurization and bottling.

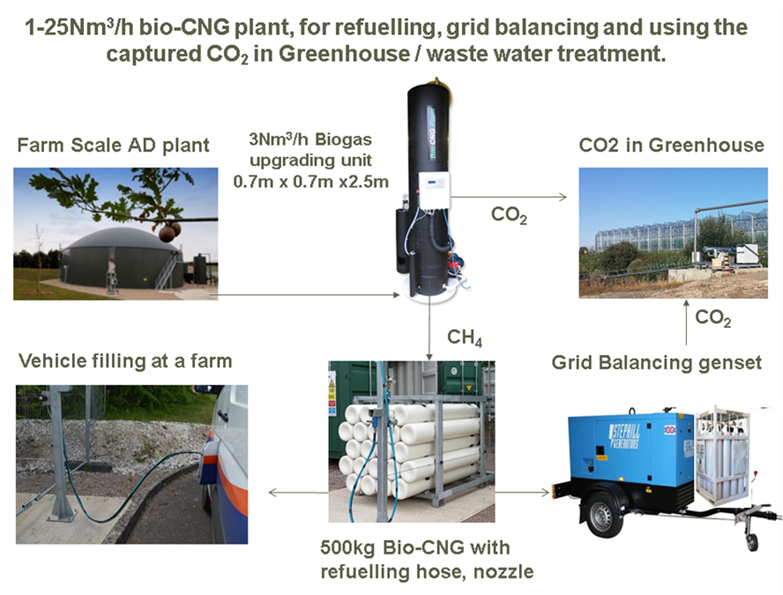

The UK’s push for decarbonisation support for decentralised energy has led several innovators to demonstrate small scale systems to take wastes through AD to bio-methane that is stored for a variety of end uses.

Research studies led by IIT Delhi led to pre-commercial trials in India in the early 2000s, and some commercialisation, although mainly focused on bottles to fuel vehicles.

Pre-commercial trials have also been reported in Kenya and our study found a pilot plant in Uganda, established by the Biogas Alliance at the national Livestock Resources Research Institute. A Nigerian farm developed plans to extend their AD/biogas operations into bottling for cooking by their surrounding communities, but concluded that the costs were too high for immediate rural neighbours, and that the nearest town was already well served by LPG.

So this is a technology that some energy researchers are taking seriously, and a few agri-businesses are experimenting. It is apparent that bottling has not yet taken off at scale and there is limited evidence in the public domain; the traditionalist engineers are still sadly shaking their heads.