- Date

- 30th May 2023

- Categories

- Electric Cooking

By Dr Simon Batchelor (Gamos Ltd., Loughborough University).

In this ‘Working PowerPoint’, I compare some of the mechanisms by which energy is transferred between a heating element and a pot of food. The Water Boiling Test (WBT) (and in many other assessments of thermal efficiencies), the protocol prescribes 3 test phases:

- Raising a specified amount of water or food to a given temperature from a cold start.

- Raising a specified amount of water or food from a hot start.

- Simmering said water for a given time (generally 45 minutes, but in some protocols 30mins). ‘Simmering’ while generally applied to a stew or water-based food, can be interpreted as ‘holding the water or food at a prescribed temperature’.

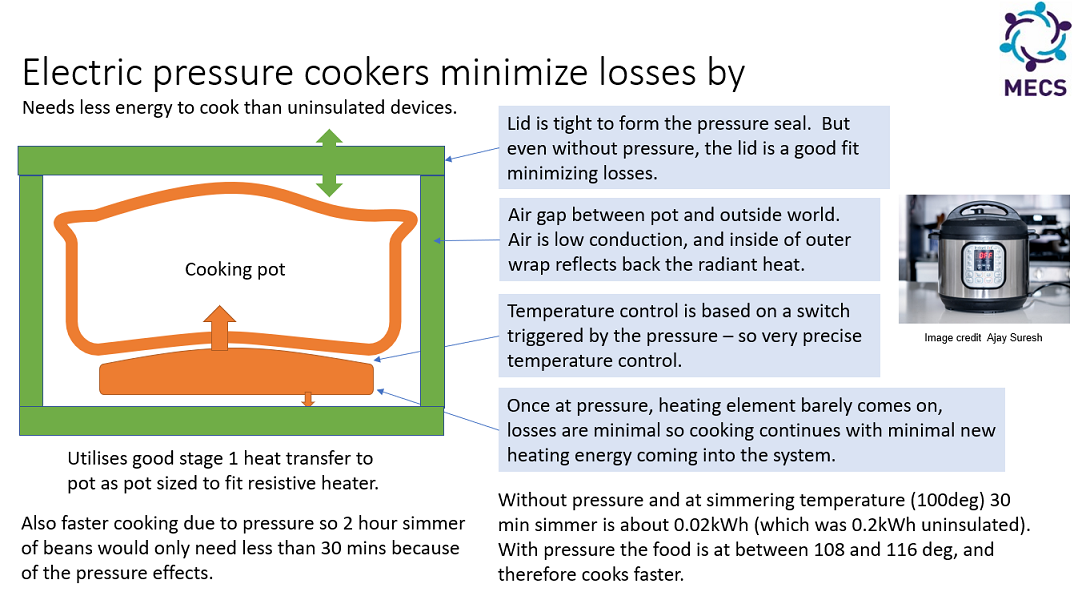

Cooking is more complex than boiling water, and so some devices such as air fryers, ovens, grills cannot be tested by the conventional WBT. However, in the PowerPoint we have taken our cue from the WBT and considered the 2 key phases to energy efficiency in cooking:

Heating of the pot of food:

- Slides 3 to 6 consider how a device raises the temperature of the food.

Losses during cooking of the food:

- Slides 8 onwards consider how the food is maintained at temperature.

There are other devices not covered in this slide deck, e.g., Kettles, toasters, grills, among others. There are also new configurations of multi cookers appearing – e.g., Hotpot grills which combine hotplates and tight control of temperature during simmering (but don’t have insulation).

Induction is often seen as the best for Phase 1 heat transfer, but this is only the case when compared to resistive heating and infra-red with a poorly matched pot. It depends on the utensils and most importantly the range of foods being cooked. It is interesting that Scott and Leach assessing multiple country field data were able to show that actually in everyday use an induction is more efficient than a hotplate in real life but only by 17% and infra-red by 8%. An EPC is 50% more efficient.

| Device | Energy used expressed as proportion of energy used by Hotplate (%) |

| Modern hobs | |

| Induction | 83% |

| Infrared | 92% |

| Insulated and automated devices | |

| Rice cooker | 77% |

| Frying pan | 83% |

| Curry cooker | 75% |

| Pressurised device | |

| Electric Pressure Cooker | 48% |

As good data analysts, Scott and Leach caveat their results by saying they need more data on a wider range of devices. MECS is currently getting the results from 22 field-based trials to get that data. The MECS programme has an ever growing body of test data on these devices both in lab settings and in real world use.

Please note this slide deck is based on the WBT, but MECS as a research programme believes every appliance should be tested with other protocols. At a minimum – Controlled Cooking Tests (CCT) (cooking a pre-determined local meal) to ensure a cultural fit to food, and piloted use in Kitchen performance test preferably, over time (what we call cooking diaries).

We hope the slide deck is a useful starting point for discussing efficiencies of appliances.

Featured Infographic: By Dr Simon Batchelor (Gamos Ltd., Loughborough University).