- Date

- 25th October 2024

- Categories

- Carbon Credit, Clean Cooking, electric cooking, Metered Methodology

By Malcolm Bricknell and Professor Matt Leach (Modern Energy Cooking Services Programme).

As part of the Sustainable Development Goals, the United Nations (UN) in 2015 set a target for every person to have access to affordable, reliable and modern energy services, including for cooking, by 2030. However, an estimated 2.1 billion people globally – nearly one in three individuals – still rely on three-stone open fires and other traditional stoves to cook their meals, using wood, charcoal, kerosene, coal and even animal waste (IEA, 2024). This is further estimated to contribute 2% of global GHG emissions (more than international aviation) as well as creating more than 50% of man-made emissions of black carbon. It also contributes to 3.2 million premature deaths annually, overwhelmingly affecting women and children who also spend significant parts of their daily lives collecting fuel and cooking in polluted kitchens. Reliance on firewood and charcoal for cooking has led to deforestation and other environmental degradation. Transitioning to clean cooking therefore delivers immense personal benefits, in addition to its strong impact on the environment and contribution to national economies.

Carbon Credits have become increasingly important as a source of funding to enable the transition to clean cooking to occur. They are transferable instruments that are certified by independent bodies with each unit representing an emission reduction of one metric tonne of CO2, or an equivalent amount of other GHGs. Carbon credits are purchased by corporate or sovereign buyers to compensate for emissions that occur elsewhere or to support climate mitigation activity. Clean cooking emission reductions (ERs) are in general notable in having very high positive impacts across a range of SDGs in addition to their carbon reduction benefits.

However, certification procedures have been complex and challenging to execute, particularly for smaller project developers. At the same time the integrity of some traditional certification methodologies based around surveys and sampling has been challenged, leading to claims that some projects receive credits for greater carbon reduction than the project delivers. Methodologies based around reliable data provided from digital technologies have been highlighted as a possible solution to help avoid potential over-crediting risks created by survey-based approaches and allowing for rigorous and regular verification of project claims.

Modern Energy Cooking (MEC) fuels (electricity, fossil or bio-based gas, liquid biofuels, pellets for gasifiers) are inherently easier to meter or measure. Combined with the increasing use of digital technology for billing, this has allowed for new methodologies for calculating emission reductions with much greater accuracy and much higher provability. Digital Monitoring, Reporting, and Verification (dMRV) is an approach for organisations to accurately measure, report, and verify these emissions using digital data and methods. These approaches leverage advanced technology and data-driven solutions to enhance transparency, accountability and efficiency in carbon accounting processes 1.

The opportunities around digital technology have been widely recognised and commented on. For example, a report produced by the World Bank a little while ago pointed out the outstanding opportunities created by dMRV solutions.

Gold Standard has started a pilot programme to test digital Measurement, Reporting and Verification (dMRV) solutions as part of its plans for end-to-end digitisation of climate and sustainable development impact certification. Running until October 2026, it will assess the potential of digital technologies to enhance the accuracy, transparency, and efficiency of monitoring and reporting for carbon credits and verified impacts under Gold Standard for the Global Goals (GS4GG).

Margaret Kim, CEO of Gold Standard has commented on it:

Digital technologies have the potential to transform the way climate and sustainable development impacts are measured and verified. This pilot is another step on our journey to bring digital efficiencies to Gold Standard to enhance the integrity of impact data and ensure that benefits are delivered faster and more effectively.

Lilian Kagume, Head of Health and Livelihoods at Climate Impact Partners has similarly mentioned:

Digital monitoring reporting and verification (dMRV) provides a good opportunity for project developers to collect and maintain high quality data. This enhances the efficiency and accuracy of monitoring and verification activities and builds on transparency and integrity of achieved emission reductions.

At a time when the reliability of other methodologies used for clean cooking projects is being challenged, dMRV has emerged as a robust way to address integrity concerns. By enabling the collection, reporting, and application of real-time usage data and fuel sales data from individual MEC products, dMRV ensures high integrity in emission reduction claims and reduces the need for costly and resource-intensive field-based verification activities.

Modern energy cooking projects have in fact been one of the most pioneering sectors in introducing digital methodologies. In October 2021, following their acceptance of new procedures proposed by Climate Impact Partners and MECS, the Gold Standard approved a new methodology allowing for certification of their Verified Emission Reductions (VERs): Methodology for Metered & Measured Energy Cooking Devices (MMECD).

The MMECD methodology is designed for cookstoves with metered or other direct fuel measurement (for example, purchase records) such as electric, LPG, biogas, bioethanol or advanced biomass pellet stoves. Calculations are based on the actual energy used by project participants when cooking with the appliances, electronically measured in the home and with data accessed remotely, with conservative assumptions for how much traditional cooking fuel use is thereby avoided. This allows for a highly efficient process for calculating emission reductions and is much more accurate, as it is based on actual energy used not on surveys and statistical approximations. If applied to every stove or fuel unit distributed by a project, MMECD can also eliminate the need for sampling – providing even more rigour and reliability for the resulting emission reductions.

VERRA, which operates the Voluntary Carbon Standard, has recently produced a new draft Methodology for Improved Cookstoves and Other Distributed Thermal Energy Generation Units which has followed a very similar dMRV approach to that of Gold Standard. Similarly, the new Comprehensive Lowered Emission Assessment and Reporting (CLEAR) Methodology for Cooking Energy Transitions under development by the 4C consortium has similarly adopted the MMECD approach for its metered component. Consequently, it is likely that these new digital methodologies will become well established and offer attractive possibilities for MEC projects to generate high integrity carbon credits. Furthermore, it is clear that some Article 6 programmes in the Official Market are adopting the MMECD as their preferred methodology for supporting clean cooking projects.

How dMRV works

Traditional clean cooking carbon credit methodologies require surveys and site visits for a sample of households to establish both the baseline use of traditional fuels and then the use of the clean cooking project devices. These approaches to data gathering are often time-consuming, expensive, lack reliability and are open to abuse. Under the MMECD or equivalent metered methodology, a monitoring device records the energy consumption of the clean cookstove. This either requires measurement of the mass of the fuel used (for LPG or advanced biofuel cookstoves) or monitoring of the electricity consumption (for an electric cookstove). Electricity consumption can be monitored in different ways, either metering electricity use directly, or metering power and the length of time the cookstove is used, with energy calculated by integrating the power consumption within the time period. The data from these monitoring devices can be sent directly to an online database, (e.g., through a GSM mobile data chip in the cookstove) or can be collected locally and aggregated via additional device(s) (such as a USB drive or smartphone), which then sends the data to the online database.

Monitoring devices can be in-built to the cookstove equipment or be connected to it externally. These monitoring devices are now proving to be reliable, durable and affordable with companies such as Geocene and Climate Solutions Consulting offering a range of stove use monitoring products and services. Companies are finding a way to integrate stove use monitors (SUMs) into a large portion or even all of their MEC devices, finding that the increased integrity of the resulting carbon credits helps command a higher price – more than compensating for the cost of deploying those SUMs.

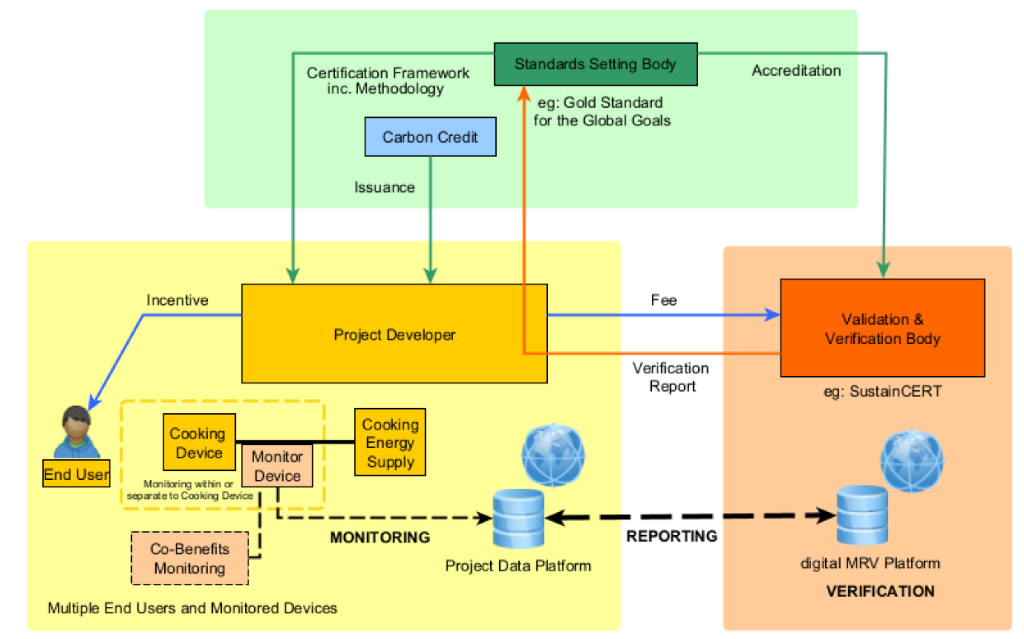

The online database will usually be part of a platform managed by the project developer. Reports can be created and provided to the Validation and Verification Body (VVB) for the organisation that sets the carbon standard being used (Gold Standard and SustainCERT in the case of the MMECD) through an automated request. The reported data is then stored on a dMRV platform, which is used periodically, along with additional project data from the project developer, to verify project impacts and issue carbon credits that the project developer may then sell. A simplified overview of such a digitalised MRV process for a modern cooking carbon project is set out below:

Advantages of using digital methodologies

In non-metered clean cooking activities, a random sample of project cookstoves is periodically selected for monitoring and verification. Standards require that samples are representative of the population and that the data should be unbiased and reliable. However, there are integrity risks that high usage households could be preferentially selected into the chosen sample. The sampling problem is compounded under survey-based methods due to “desirability bias”. Survey participants frequently indicate inflated adoption and usage rates to impress developers, and they may also suffer from unintentional recall bias. However, it can be acknowledged that the regular household visits to conduct surveys and kitchen performance tests help to maintain a good link with the project implementers.

Digital methodologies do not need to rely on such surveys to demonstrate MEC device uptake and usage. They directly track project stove and fuel use in participating households through meters or fuel sales data. They also do not require the estimation of “stacking” – the use of additional cookstoves or fuels in addition to the project device – as they calculate emission reductions based on accurate measurements of actual project fuel usage, and evidence of the traditional fuel use in the baseline that is avoided.

Risks from sampling can also be substantially eliminated by individually monitoring every cooking device. Although this option might appear prohibitively expensive, cooking devices with integrated meters that allow for remote data collection represent a credible option to achieve this in a relatively cost-effective way. Where clean cooking companies are helping finance cookstove use through Pay-as-you-Go arrangements with customers, they will already build in remote monitoring as part of their business model, and the additional costs of metering for carbon purposes are much lower. Imperfect connectivity and technical reliability mean that estimates to fill data gaps may be required with digital monitoring, but solutions to handle these situations are available. Projects outlined below by ATEC, EcoSafi, BURN and UpEnergy demonstrate that 100% metered or measured stove projects are commercially viable.

A major opportunity for data transparency enabled by digital tools is to publish project data in real-time. A good example for this is the Carbon Credit Dashboard developed by ATEC mentioned below or the Prospect platform and Appliance Demand Platform by A2EI, which enable carbon credit buyers to directly track the impact of their financial contribution. The integration of these technologies within a dMRV system facilitates real-time communication of project outcomes, resulting in faster, more consistent, and precise reporting. These platforms employ advanced algorithms and modelling techniques to provide highly accurate measurements of greenhouse gas emissions, reducing the margin for error. They generate automated reports and dashboards that streamline the reporting process, making it easier for organisations to comply with regulatory requirements and communicate their sustainability efforts to stakeholders as well as facilitating third-party verification by providing auditors with access to verified data and audit trails, ensuring the credibility of emission reduction claims 2.

A further significant advantage of real-time data will be the ability of certification bodies to speed up the issuance of credits which will then allow project developers to access funds faster with consequent improvements to cash flow. Other cost reduction benefits should occur from facilitating the validation and verification processes required by certification bodies, as the relevant organisations (VVBs) involved in checking the integrity of these results will be able to conduct checks at a system level rather than needing to check particular survey results presented.

Equitable revenue sharing from carbon credit income has become a major issue and is a feature of both the Integrity Council for the Voluntary Carbon Market (ICVCM) Core Carbon Principles and the Responsible Carbon Finance Principles and Code of Conduct being developed by the Clean Cooking Alliance. Some developers such as ATEC have already shown how digital technology can cheaply, accurately and transparently address the combined needs of transparency and equitable revenue sharing, essentially via a reverse PAYGO payment or an offsetting credit. This is another major advantage of digital technology.

Projects using the MMECD methodology

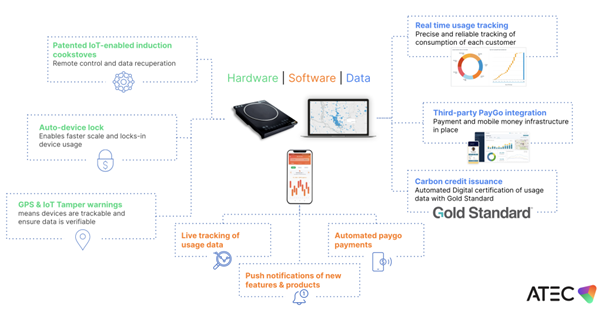

ATEC Global was one of the earliest project developers to certify a project with Gold Standard using the MMECD, for induction cookstoves in Bangladesh and Cambodia. Together with the efforts of other pioneering project developers they have effectively demonstrated the technical and commercial viability of the new methodology. ATEC was the first project design certified under MMECD with credits calculated using 100% of metered customer data.

The ATEC project is also a very good example of how dMRV can efficiently address the issues of transparency and equitable revenue sharing. ATEC has been pioneering this approach, under its “Cook-to-Earn” model. Fair Climate Fund has worked with ATEC to show how the advantages of this approach can be enhanced further, thereby achieving higher revenues for consumers, by taking part in this project through the additional Fairtrade Certification process. This, inter alia, requires very high standards of equitable revenue sharing.

ATEC CEO Ben Jeffreys comments:

Digital Verification through IoT and satellite data is a big step forward to building trust in carbon credits. The MMECD, which allows devices to be integrated with technology like IoT sim cards to verify exact usage data, is a great example of how this can work in practice. With these technologies we can unlock the 1 gigaton of carbon assets households in the global south are holding, then connect them into global carbon markets to turn it into an income stream.

EcoSafi provides an advanced gasifier to customers who purchase its sustainable biomass fuel pellets. Its project in Kenya (GS11352) was the second issuance under the MMECD globally and the first in Africa.

It was also the first MMECD project with issued credits calculated using 100% of measured customer data (rather than sampling). By digitally tracking and verifying fuel sales for and assigning individual baselines to each of its customers, EcoSafi has addressed the challenge of over-crediting risk and generated high integrity credits. Consequently, it has received the rating agency BeZero Carbon’s first ‘A’ or higher rating for cookstoves. It has also recently sold all ERs generated from its first stove and pellet fuel distributed in 2021 through the end of 2024 for a price of $35, reflecting that buyers recognize this integrity and the value it provides to them with premium pricing. Recent trends in the Voluntary Carbon Market have seen buyers increasingly turning to rating agencies as a means of independent assurance around integrity of emission reduction claims and the associated risks. It is therefore very encouraging to see this high-level rating given to EcoSafi’s project, which should be seen as an endorsement of the MMECD methodology itself.

As EcoSafi CEO, Tom Price notes:

Using MMECD to meter and measure 100% of customer fuel sales and stove usage can help put a clean cooking project like ours in the same elite group of highly verifiable, highly provable and low risk projects as advanced carbon removals. Being data-precise to each customer wherever possible while using ultra-conservative inputs for everything else yields high value climate impacts that buyers are demanding- and for which they are willing to pay a robust price.

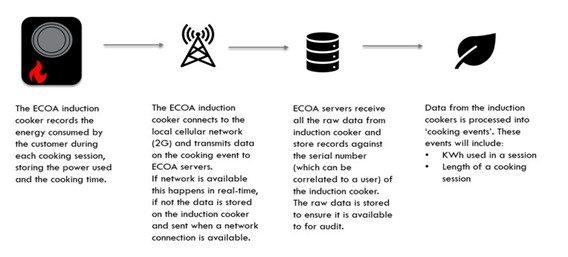

BURN Manufacturing is using the metered methodology to scale electric cooking across Africa. BURN’s ECOA cookers are GSM enabled and transmit real-time electric power consumption data to BURN’s proprietary data management software, “ECOA Nexus”. The technology allows for real-time monitoring of energy consumed to cook, which allows for accurate measurement of emission reductions, significantly improving the integrity of carbon credits. This data management system enables 100% metering under Gold Standard’s Metered Methodology (MMECD) and also allows for financing on Pay-as-You-Cook (PAYC) for customers who cannot afford the full payment upfront as it integrates directly with mobile money payment systems allowing customers to pay back their loans flexibly.

BURN’s ECOA Electric Induction Cooker is now deploying at scale across multiple countries in Africa and will be generating credits via the MMECD. To help build out the evidence base for the metered methodology, BURN has collected baseline fuel consumption data using Kitchen Performance Tests, Cooking Diaries and Controlled Cooking Tests and has been working with MECS in collating data to assess Specific Energy Consumption (SEC) defaults.

In 2023, UpEnergy issued the world’s first carbon credits linked to emissions reductions from replacing charcoal cooking with electric clean cooking devices. These devices include in-built metered technology for continuous monitoring and feature a redesigned interface tailored to local cooking habits, supporting local-client adoption and convenience of use.

Today, UpEnergy is leading what is currently the largest bilateral compliance electric cooking initiative in Ghana. Using the MMECD as a foundation, the project aims to deploy 200,000 electric stoves in Ghana over the next three years. This effort is part of UpEnergy’s broader expansion of zero-emission electric stoves across Sub-Saharan Africa, with additional projects in Uganda, Tanzania, and Zambia.

UpEnergy’s zero-emission electric stoves feature built-in sensors that continuously measure real-time consumption data, capturing up to 13 months of cooking activity for accurate comparisons with baseline stoves and can be equipped with GSM modules for remote data access. In addition to electric cooking, UpEnergy has integrated dMRV capabilities into its locally manufactured fuel-efficient cookstoves, equipped with IoT-based usage monitors. These monitors provide real-time temperature data, complementing other data collection methods to create an accurate picture of fuel savings across all UpEnergy clients. Both these technologies are supported by a planned real-time app to monitor the usage of units across different markets and projects, widening its digital capabilities and driving deeper insights from its clients.

As Francisco Cockbaine, UpEnergy’s Director of Product said:

UpEnergy’s digital MRV systems across all our technologies provide something invaluable—real, human insights into how people use our products in their daily lives. By monitoring cooking modes, dishes, and durations, we gather detailed data that goes beyond numbers—it helps us understand the behaviors and needs of the communities we serve. This aligns with our Client First approach, which is centered around listening to and learning from our clients, to provide technology that is not only effective but also culturally relevant and aligned with the daily challenges our clients face across Africa.

SDG Impact Co-benefits

One reason for the popularity of the Gold Standard VERs is their well-developed methodology for certifying non-carbon Sustainable Development Goal (SDG) impacts (co-benefits), which help projects command higher prices for their VERs.

Most cooking projects to date have measured these benefits rather superficially at the activity level rather than at the outcome and impact levels due to the cost and complexity of analysing these impacts in more detail and the limited levels of information required to date by offset buyers. New initiatives including requirements from the ICVCM will impose higher standards on project developers, whilst corporate buyers are in any case becoming more discriminating in their requirements to meet their Environmental, Social and Governance (ESG) goals as well as their climate targets.

A major obstacle to better reporting of co-benefits has been the administrative costs of measuring and demonstrating these SDG impacts. Digital technology can play an important role in enabling reporting at a wholly different level to earlier practices, especially where impact measurement can “piggyback” off the data platform required for carbon credit certification.

Some SDG impacts should be relatively straightforward to demonstrate using quantitative usage data- for example in calculating time saved for women in cooking and fuel collection. Additionally, digital technology could also hold the key to unlocking the cost-effective calculation of some very important but harder to demonstrate SDG impacts. This may apply around measurements of particulate matter including SLCPs/black carbon and related health impacts. While cooking projects have been linked to reduced indoor air pollution in many studies, the resulting health outcomes have usually been difficult to accurately quantify-at least cost effectively. With the launch of digital tools for SDG reporting such as the Digital SDG Impact Tool – Gold Standard for the Global Goals, it will allow for more transparent quantification and reporting of SDG impacts, which builds on the milestones being achieved with the MMECD methodology.

Digital technology offers an outstanding opportunity to transform impact finance for MEC projects by reducing cost and increasing the accuracy and integrity of data. This could in turn catalyse urgently needed funding to accelerate the transition to modern energy cooking, as donors increasingly require accurate and cost-effective reporting of impacts as a condition of providing their support.

Challenges in using cooking methodologies

Methodologies based on digital technology cannot achieve good results unless accurate data and realistic input values are used where applicable. The calculation of emission reductions depends on a number of parameters other than fuel/electricity consumption which can have a material impact on the overall outcome of the emission calculation. A notable example of this is the fraction of non-renewable biomass (fNRB) that determines the non-renewable part of the traditional biomass displaced by the project, which is the portion that contributes to the emission reductions generated. This affects projects of any sort that involve biomass and forestry, not just cooking, and appropriate and conservative benchmarking is required to maintain reporting integrity. Detailed research and consultation in this area is ongoing, coordinated through the UNFCCC, and results around this could be expected as soon as end 2024, which should address this issue.

The cost of monitoring equipment, data communication, IT systems and database storage has been highlighted as a significant challenge to the implementation of dMRV systems, although equipment prices are dropping with economies of scale. Alongside digital data collection, site visits may still be required, albeit at a reduced level, for example to implement surveys to measure co-benefits, investigating fuel stacking and equipment maintenance, so this cost is not totally removed.

Data security throughout the whole data chain is paramount to the integrity of any carbon credit claims. This includes within the monitoring device, through any communication path and within IT systems. Implementing secure data paths requires specialist knowledge which may add to the complexity and cost for a project developer implementing dMRV systems, although more standardised platforms and equipment are becoming available helping to reduce this burden.

One issue that does arise with transition to improved cooking solutions is the “rebound effect”. Improvements in stove efficiency and cost are associated with households potentially increasing the amount they cook. Although much anecdotal evidence suggests that this should not be a major concern for MEC projects or for the poorer households that are typically their focus, there is scope for further research around this issue in order to more scientifically assess its impact.

Comparative Research

MECS recently commissioned AGS Carbon Advisory to conduct a study of the workings of the MMECD. AGS has made a comparative analysis of MMECD with other methodologies such as Technologies and Practices to Displace Decentralized Thermal Energy Consumption (TPDDTEC) v4.0 and the draft Comprehensive Lowered Emissions Assessment and Reporting Methodology (CLEAR). Their key findings indicate that the current MMECD methodology provides a robust yet conservative framework that yields high quality Emission Reductions with strong environmental integrity, especially in comparison to other methodologies available to the cooking sector. AGS also identifies opportunities to further improve this sector-best methodology, including clarifying how key procedures and inputs can be applied consistently across different projects and project developers and imposing requirements for a more rigorous approach to sampling.

A number of organisations are collaborating to develop recommendations around good practice for digital methodologies with a view to increasing their uptake and pre-empting their misuse. The recommendations of the AGS report will assist in formulating recommendations to Gold Standard and other Standards regarding measures to further tighten rules applying to methodologies and ensure developers have clarity in the requirements. One reason for the growing confidence in the MMECD (and related metered methodologies) is the more realistic and actually quite conservative levels of emission reductions that projects are calculated to achieve, which is also borne out and demonstrated in the AGS report.

Conclusion

Carbon credits are an essential source of funding for the urgently needed acceleration of the transition to clean cooking. They have been widely recognised as having very high positive impacts on the lives of poorer populations across a range of SDGs in particular health, gender, environment and livelihood in addition to their carbon benefits. This is not the case for many other carbon credits.

Modern energy cooking solutions are being shown to be increasingly technically and financially viable and have much higher developmental impacts than traditional unsophisticated improved cookstoves.

Digital technology has created the opportunity for the availability and maintenance of high-quality data which leads to integrity and transparency in monitoring, reporting and verification of modern energy cooking projects, and this can be a valuable resource in restoring the confidence of buyers in the sector.

There is a determination from leading market participants that past mistakes in overclaiming should not be repeated. Good working practices around the use of digital technologies can help to ensure that integrity standards can be upheld, and different parties should continue to cooperate to make sure these are respected in practice and maintained going forward. Inevitably, new technologies and related practices will arise which can offer scope for further improvements in market practices, and it will be important to ensure that these uphold high integrity standards at the same time as delivering greater efficiencies.

***************************************************************************************************************

1: “A review of the standards, methodologies, technical needs and available resources related to digital

monitoring, reporting and verification for modern cooking devices in the context of carbon finance” Little et al. (2023).