- Date

- 24th July 2020

- Categories

By Dr Jaqi Lee, S2A Associates, Sustainability Systems Analysis.

The phrase, critical raw materials (CRMs) gets heard a lot in design, but what does this actually mean, and what is a critical material. There have been numerous studies to define and evaluate the minerals and metals found on and in the earth’s surface [1],[2].

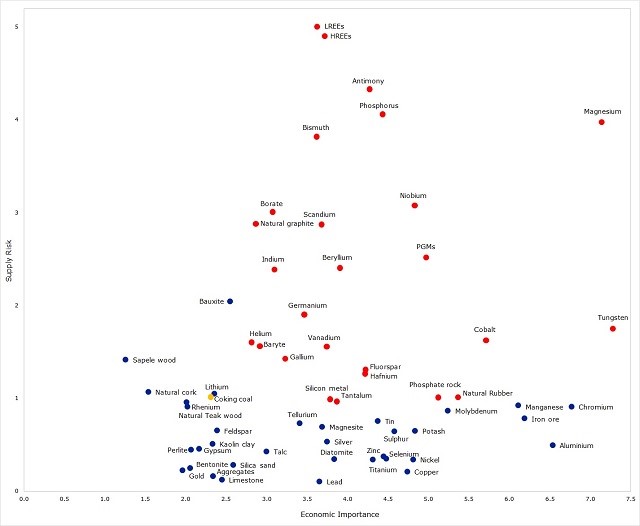

From these it can been seen that criticality is actually a subjective term, a combination of a range of factors that vary over time, geography and political landscape. However, it’s not clear cut how criticality is measured, each criticality report has different assumptions, timelines and goals. To measure supply issues, one commonly used index is the Herfindahl-Hirschman index (HHI), which looks at the monopoly of supply; put simply, the fewer sources for a material, the worse the HHI score. Other supply measures include recycling rate, substitutability, price volatility and likely demand changes. The other side of critical material risk assessment is understanding the impact that a restriction in supply might cause. This is hugely subjective, and measures used to evaluate this include, (but are not limited to), potential impact on revenue, price volatility and environmental impacts. As with all multifactor decisions, aggregation (or not) of the supply and impact metrics leads to its own issues; namely how to bring together a wide-ranging set of indicators to produce a meaningful outcome [3].

Notwithstanding the above, it is possible to create a list of those materials that are considered to be fundamental for the global economy to function, but are potentially in short supply. The EU have created a list, the EU 27, (see figure 1) and other organisations have also created critical material lists, for example the US Government have identified 35 minerals deemed critical to the US National Security and Economy [4]. There are some surprising materials included on these lists, such as magnesium, natural rubber and coking coal, as well as the more usual suspects; rare earths and platinum group metals. With each review of the lists, more minerals are added.

All well and good, you might say, but my design is ok because it doesn’t have any of these materials in it. Your supply chain, however, may be an entirely different story. For example, some turning or milling operations require tungsten tipped cutting devices, without which, the quality of the finished product may be reduced, or it may not even be possible to manufacture at all. A serious shortage of supply in the tungsten market would reduce the tooling available, reducing the availability of machine parts that are needed to make components for your product.

For the MECS programme, the main materials in the design and manufacture of modern energy cooking devices are steel, aluminium, which in themselves do not feature in the critical materials. But metals production required coking coal, and this could be a potential future issue. Electronics for controlling electric pressure cookers (EPC), inverters and solar home systems (SHS), do contain some critical materials. However, a far greater concern is that relating to the materials in lithium ion battery design, as batteries are a fundamental component of SHS and for supporting weak grids and mini grids. Three of the main four materials (cobalt, natural graphite and silicon (metal)) are on the CRM list and the fourth, lithium, is of considerable interest as it plays such a fundamental role in these devices. And for solar panels themselves (depending on the type), up to eight metals face supply challenges.

By: Yo-Co-Man / CC BY-SA (https://creativecommons.org/licenses/by-sa/4.0)

The implications of this challenge for the roll-out of modern energy cooking across is not insignificant. If we consider how many batteries, solar panels and associated devices are needed to move to cleaner cooking solutions, this will require an ever-larger proportion of these materials from the market. The clean cooking market is not the only customer for these materials, so a rapid ramping up of clean cooking demand could lead to price rises as the materials are in short supply, pushing up product prices. Higher product prices cause the financing schemes for the equipment more difficult to make affordable, and could lead to reduced uptake as the systems will be out of the economic reach of those who most need them.

By Michal Klajban / CC BY-SA (https://creativecommons.org/licenses/by-sa/4.0)

But it is also an opportunity for the clean cooking market; careful design of products, how the products are provided to the customers, and effective collection and take back systems could open up valuable reuse, repurposing and recycling industries. These issues need to be thought about up-front, to enable the right policies, systems and skills to be established in good time.

[1] 2017: Study on the review of the list of Critical Raw Materials. Doi: 10.2873/876644

[2] 2015: Criticality of metals and metalloids. Graedel et al. Proceedings of the National Academy of sciences of the unites states of America. Doi: 10.1073/pnas.1500415112

[3] 2015: Recommendations for assessing materials criticality. Lloyd et al. Proceedings of the Institution of Civil Engineers – Waste and Resources Management. Doi: 10.1680/warm.12000002

[4] 2018, US List of Critical Materials: https://www.federalregister.gov/documents/2018/05/18/2018-10667/final-list-of-critical-minerals-2018. Accessed 21/5/20.